1

1Design activities

To draft detailed drawings, engineers of TCS HYDRO need the following:

- Technical parameters for designing. For example, penstock diameter, static pressure, hydrodynamic head, flow rate, etc.

- Design drawings of a facility, where equipment is to be installed

- Designation of a location, where new equipment will be installed

- Data on the crane facilities at the site

- Customer's specifications

- Overall and mounting dimensions in case of the equipment replacement or repair

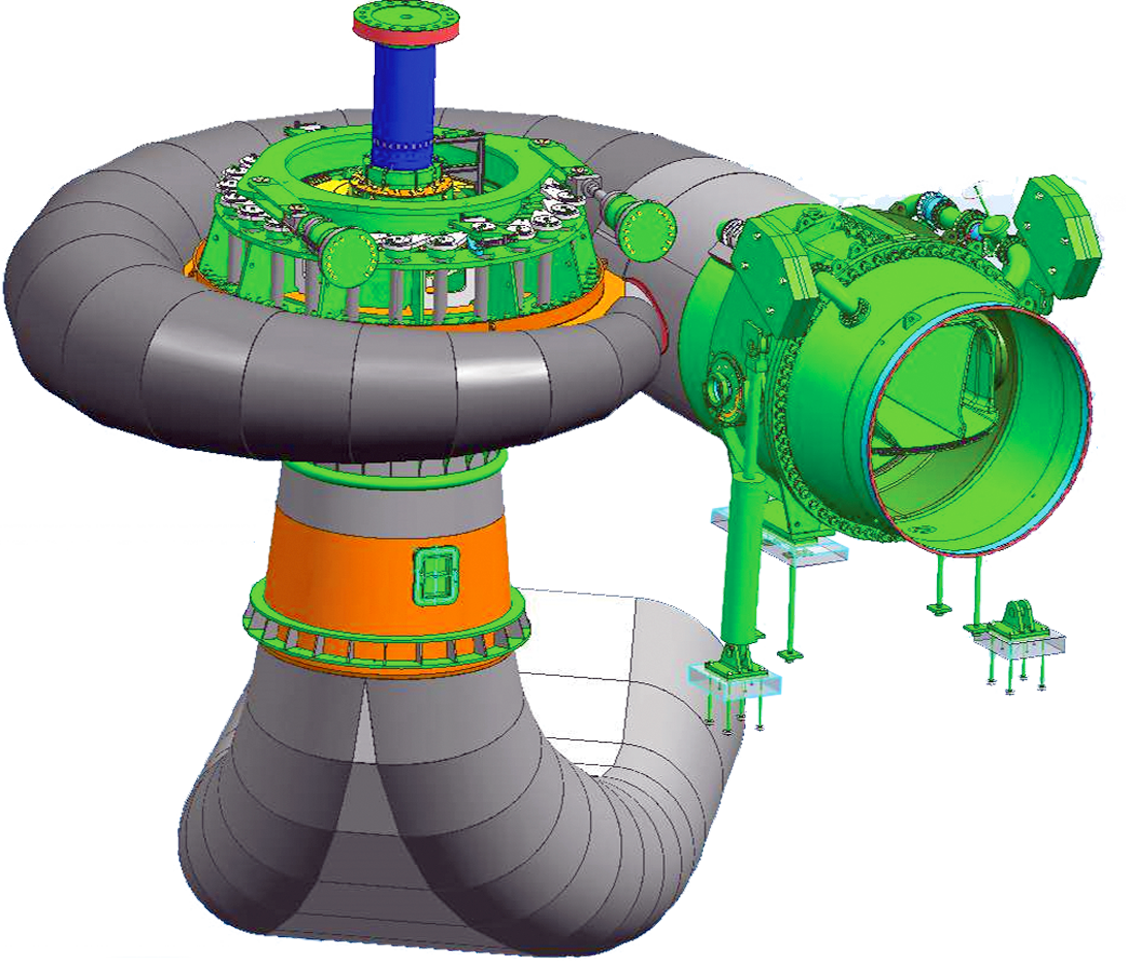

Creating a 3D model makes it possible to precheck the equipment assembly to thereby provide for the equipment assembling accuracy during installation, and is also used in the FEM calculation. Besides, 3D modeling facilitates making changes in the project. Designing yields detailed drawings and specifications that are put into production.

TCS HYDRO develops detailed schemes and guidelines for dismantling/installation of the equipment ensuring high quality of dismantling-and-installation work and compliance with the facility completion deadlines. In addition, to provide for the qualified operation of the equipment, TCS HYDRO develops an operating and maintenance manual.

2

2Manufacture

In the process of manufacture we use materials, monitoring procedures and techniques pursuant to applicable standards and regulations. As such, TCS HYDRO place a priority on the standards and regulations equivalent to ASTM or DIN standards and regulations.

Technical supervision and testing of main parts and assemblies are conducted in accordance with the quality control program developed by TCS HYDRO.

To ensure a proper quality of the equipment manufacture, specialists of TCS HYDRO maintain a design supervision over the production cycle including the material inspection and in-process inspection during manufacture of main parts, conduct fit-up assembly tests for main components including their hydraulic and functional testing.

3

3Delivery/Transportation

Large-sized parts (for example, a spherical valve, an inlet pipe, an expansion joint) are transported on platforms within the basic loading gage, wherein all mating surfaces are protected.

Crates used for packing parts and assembly units are designed and manufactured as per applicable standards. Displacement of equipment inside packages is excluded.

Each package unit with the equipment packed comes with a corresponding packing list. Shipping marking of each package unit and a corresponding slinging point as well as marking of parts are performed in accordance with the requirements of applicable standards and technical specification.

4

4Installation supervision and commissioning

TCS HYDRO sends its authorized specialists to the site to conduct technical supervision over the compliance of the dismantling-and-installation operations with the requirements of the project documentation.

Upon completion of the installation work, TCS HYDRO specialists perform pre-commissioning activities on the installed equipment so that to put it into operation, including testing as per the programs developed.

Besides, TCS HYDRO conducts technical training for the operational staff so that to familiarize it with the equipment design features and operating conditions.